BOONLION SHARP KNIVES "RIAMHMOOB"

Engineered to Cut. Built to Last.Our cold and hot-forged steel knives are meticulously crafted for those who demand strength, style, and uncompromising performance. Designed for raw power, refined aesthetics, and unmatched reliability.

-

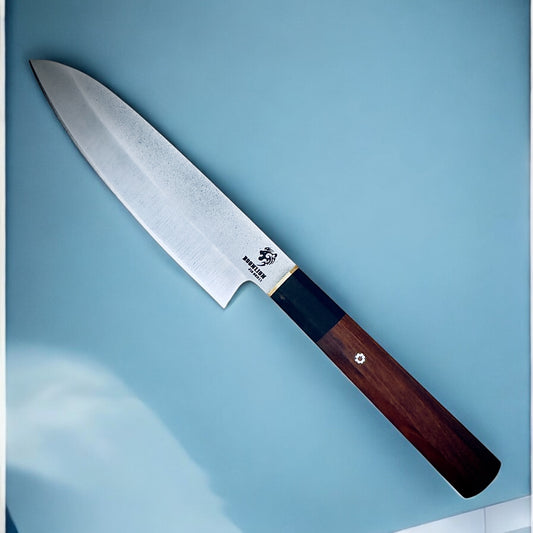

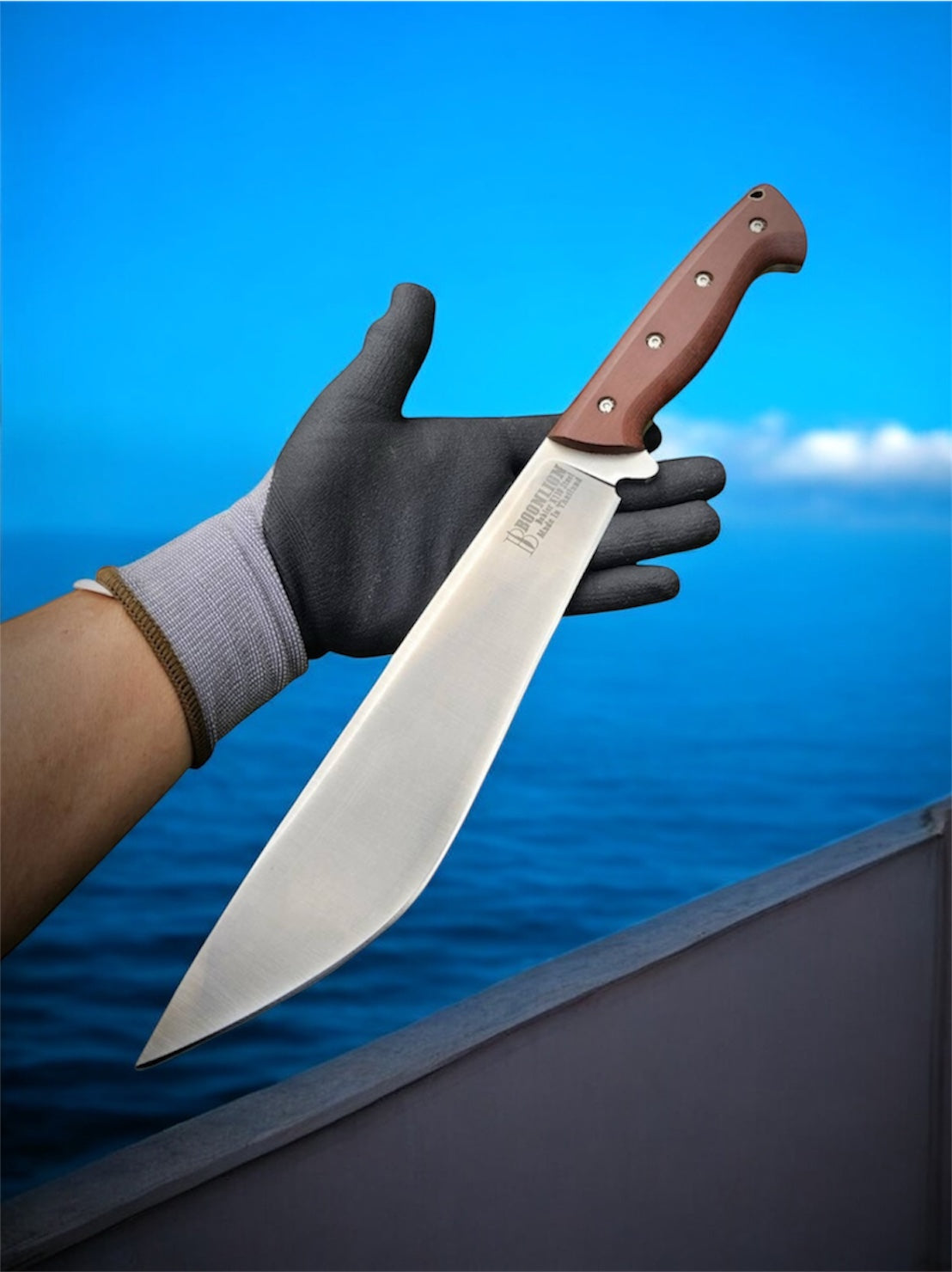

10" BOONLION Modern Knife "FRB-32MnCrB5"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $165.99 USDRegular priceUnit price / per$273.89 USDSale price $165.99 USDSold out -

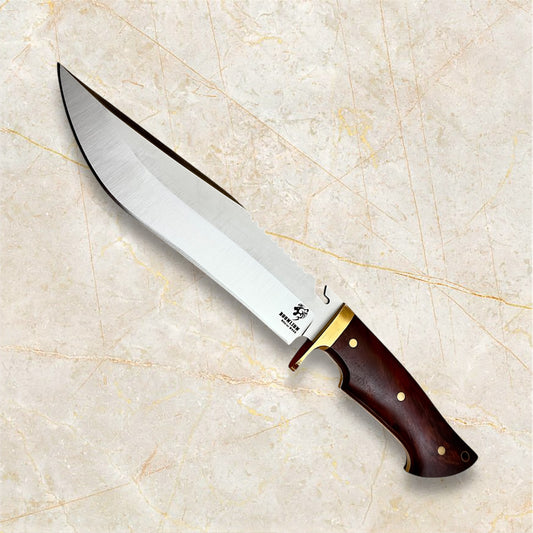

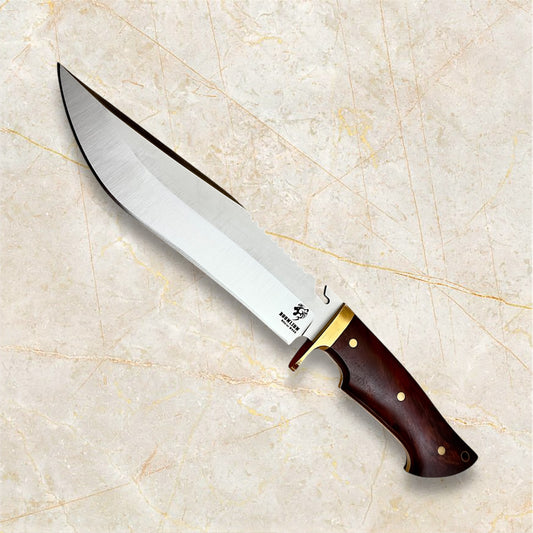

10" HmongBowie

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $200.00 USDRegular priceUnit price / per -

Sold out

Sold out10" Thai E-Nep Knife

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $299.99 USDRegular priceUnit price / per$450.00 USDSale price $299.99 USDSold out -

10" Thai E-Nep Knife (France Boron Alloy Steel)

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $165.00 USDRegular priceUnit price / per$265.00 USDSale price $165.00 USDSold out -

Sold out

Sold out10.3" Thai Rambo Knife Cleaver

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $165.99 USDRegular priceUnit price / per$270.64 USDSale price $165.99 USDSold out -

11" BOONLION Machete Knife "BRM-N695"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $520.00 USDRegular priceUnit price / per$540.00 USDSale price $520.00 USDSold out -

11" BOONLION Machete Knife "JRM-SKD11"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $520.00 USDRegular priceUnit price / per -

11" Hmong Classic Knife

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $220.00 USDRegular priceUnit price / per -

271 Layers Boonlion HmongKnife Copper Damascus AU

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $2,200.00 USDRegular priceUnit price / per -

271 Layers Copper Damascus AU

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $2,000.00 USDRegular priceUnit price / per -

6.7" BOONLION Tactical Camp Knife "BRH-N965"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

6.7" BOONLION Tactical Camp Knife "JRH-SKD11"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

7" BOONLION Mini Cutting Knife "BRM-N965"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $400.00 USDRegular priceUnit price / per -

7" Hand-Forged Serbian Cleaver

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $40.00 USDRegular priceUnit price / per$65.00 USDSale price $40.00 USDSale -

7" Hmong Bowie Copper Laminated AU

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $450.00 USDRegular priceUnit price / per -

Sale

Sale7" Mini-Rambo Knife

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $135.23 USDRegular priceUnit price / per$222.75 USDSale price $135.23 USDSale -

7.4" Japanese Hitachi SLD Steel (JIS SKD11) Cleaver Knives with G10 Black glass fiber handle.

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $90.00 USDRegular priceUnit price / per$120.00 USDSale price $90.00 USDSale -

7.5" BOONLION Nakiri Knife "BRH-N695"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

7.5" BOONLION Nakiri Knife "JRH-SKD11"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

7.6" BOONLION Chef Knife "BRH-N695"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

7.6" BOONLION Chef Knife "JRH-SKD11"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

Sold out

Sold out7.9" Beef & Pork Bone Cleaver

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $45.39 USDRegular priceUnit price / per$55.59 USDSale price $45.39 USDSold out -

7.9" Rectangle Bone Cleaver for Beef & Pork

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $50.00 USDRegular priceUnit price / per$74.99 USDSale price $50.00 USDSold out -

8" 67 Layers Damascus Chef Knife

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $85.00 USDRegular priceUnit price / per$99.89 USDSale price $85.00 USDSale -

8" 73 layers 14Cr14V3 Power Damascus Chef Knife

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $99.99 USDRegular priceUnit price / per$129.99 USDSale price $99.99 USDSold out

BOONLION HMONG CLASSIC & MODERN KNIVES

At BOONLION, we carefully select only high-performance steels to forge our Hmong knives—each chosen for its strength, edge retention, and toughness. Our lineup includes 7Cr17 is a perfect match for chopper knives, offering a strong balance of durability, corrosion resistance, and toughness. It resists rust even during heavy meat and bone work. Its 0.7% carbon content allows it to reach 55–58 HRC—hard enough for a sharp edge, yet tough enough to handle impact without chipping. 1080+ high-carbon steel provides excellent hardness and is favored for its reliable performance in cutting and chopping. Alloy steels offer balanced toughness and wear resistance for blades that take a beating and stay strong. For higher-grade performance, 9Cr18 steel is a premium knife steel with about 1% carbon and 18% chromium, known for its exceptional hardness, edge retention, and corrosion resistance. Its vacuum deep-cooling heat treatment creates a sharp, durable edge that balances toughness and sharpness—making it perfect for heavy-duty chopping of meat and bone without dulling or rusting, and ensuring long-lasting, low-maintenance performance. SUJ2 high-carbon steel from Japan is a top-tier choice for chopper knives, offering excellent hardness, edge retention, and wear resistance. Its fine grain structure allows for a sharp, precise edge, while heat treatment boosts durability and strength. Perfect for chopping pork, beef, or game, SUJ2 delivers reliable performance with every cut. N695 by Böhler provides excellent corrosion resistance, sharpness, and a clean grind. And for collectors and professionals. SKD11 and K110 are both high-quality tool steels with high carbon and chromium content, providing excellent hardness, wear resistance, and toughness. SKD11 is known for its strong edge retention and impact resistance, making it reliable for heavy chopping and industrial use. K110 offers outstanding hardness, edge stability, and better corrosion resistance compared to many tool steels, ensuring long-lasting sharpness. Together, these steels deliver durable, sharp edges ideal for premium chopper knives that withstand heavy use without dulling or damage. Finally, our Apex Ultra Damascus combines high-carbon laminated steel’s beauty and cutting power, marrying tradition with elite metallurgy.

Premium Steel Selection — Built for real-world power, edge control, and long-lasting performance.

-

271 Layers Boonlion HmongKnife Copper Damascus AU

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $2,200.00 USDRegular priceUnit price / per -

271 Layers Copper Damascus AU

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $2,000.00 USDRegular priceUnit price / per -

7" Hmong Bowie Copper Laminated AU

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $450.00 USDRegular priceUnit price / per -

10" HmongBowie

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $200.00 USDRegular priceUnit price / per -

11" Hmong Classic Knife

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $220.00 USDRegular priceUnit price / per -

BOONLION The HmongTiger2

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $550.00 USDRegular priceUnit price / per -

The Hmong Knife - HmongTiger1

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $550.00 USDRegular priceUnit price / per -

BOONLION RiamHmoob BL1

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $200.00 USDRegular priceUnit price / per -

BOONLION RiamHmoob BL5

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $200.00 USDRegular priceUnit price / per -

BOONLION RiamHmoob BL4

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $165.00 USDRegular priceUnit price / per$199.00 USDSale price $165.00 USDSale -

BOONLION RiamHmoob BL3

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $165.00 USDRegular priceUnit price / per$199.00 USDSale price $165.00 USDSale -

BOONLION RiamHmoob BL2

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $165.00 USDRegular priceUnit price / per$199.00 USDSale price $165.00 USDSale -

11" BOONLION Machete Knife "JRM-SKD11"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $520.00 USDRegular priceUnit price / per -

11" BOONLION Machete Knife "BRM-N695"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $520.00 USDRegular priceUnit price / per$540.00 USDSale price $520.00 USDSold out -

7" BOONLION Mini Cutting Knife "BRM-N965"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $400.00 USDRegular priceUnit price / per -

8.7" BOONLION Black Bowie Knife "BRB-N695"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $450.00 USDRegular priceUnit price / per -

Sold out

Sold out8.7" BOONLION Bowie Knife "BRB-N695"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $450.00 USDRegular priceUnit price / per -

9" Thai-Rambo Knife SUJ2

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $299.00 USDRegular priceUnit price / per$350.00 USDSale price $299.00 USDSale -

10" Thai E-Nep Knife (France Boron Alloy Steel)

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $165.00 USDRegular priceUnit price / per$265.00 USDSale price $165.00 USDSold out -

Sold out

Sold out10" Thai E-Nep Knife

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $299.99 USDRegular priceUnit price / per$450.00 USDSale price $299.99 USDSold out -

6.7" BOONLION Tactical Camp Knife "BRH-N965"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

6.7" BOONLION Tactical Camp Knife "JRH-SKD11"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

10" BOONLION Modern Knife "FRB-32MnCrB5"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $165.99 USDRegular priceUnit price / per$273.89 USDSale price $165.99 USDSold out -

Sold out

Sold out10.3" Thai Rambo Knife Cleaver

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $165.99 USDRegular priceUnit price / per$270.64 USDSale price $165.99 USDSold out -

9.3" BOONLION Dragon Head Long Cleaver

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $75.59 USDRegular priceUnit price / per$129.44 USDSale price $75.59 USDSold out

BOONLION Professional Chef Knife

At BOONLION, we carefully select premium steels known for their razor-sharp edges, long-lasting sharpness, and excellent performance in professional kitchens. For our chef knives, we use a range of proven steels such as 1.4116, a German stainless steel valued for its corrosion resistance, easy sharpening, and reliable edge retention. VG10, 10Cr18MoV, 12Cr18MoV, and 14Cr18MoV steels are premium high-chromium stainless steels widely respected for their excellent hardness, corrosion resistance, and edge retention—qualities that make them ideal for high-performance knives. When treated with vacuum deep-cooling heat treatment, these steels achieve even greater strength and durability. This advanced process uses precisely controlled heating and cooling cycles to reduce internal stresses, refine the steel’s microstructure, and enhance carbide formation. The result is a blade with superior hardness, improved toughness, and an exceptionally sharp, long-lasting edge. Additionally, the high chromium content (ranging from 10% in 10Cr18MoV to 14% in 14Cr18MoV) ensures outstanding resistance to rust and corrosion, even in wet or acidic kitchen environments. Knives made from these steels with vacuum deep-cooling treatment deliver the perfect balance of sharpness, durability, and low maintenance—making them highly reliable tools for professional chefs and serious home cooks alike. We also use Damascus steel, layered for strength and admired for its beauty, combining both performance and aesthetics. Suj2, a high-carbon Japanese steel, provides excellent hardness and a fine edge ideal for precision work. For heavy-duty kitchen tasks, we include SKD11 and Böhler N695, high-carbon tool and stainless steels known for exceptional toughness, edge stability, and long-term durability. These steels are the foundation of every Boonlion Professional Chef Knife—designed to deliver superior control, strength, and reliability in every cut.

-

BOONLION Bunka Knife 8.5"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $52.00 USDRegular priceUnit price / per -

BOONLION Sashimi Knife 8.5"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $52.00 USDRegular priceUnit price / per -

8" 73 layers 14Cr14V3 Power Damascus Chef Knife

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $99.99 USDRegular priceUnit price / per$129.99 USDSale price $99.99 USDSold out -

8" 67 Layers Damascus Chef Knife

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $85.00 USDRegular priceUnit price / per$99.89 USDSale price $85.00 USDSale -

8" BOONLION SUJ2 Chef Knife, Bamboo Handle

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $90.00 USDRegular priceUnit price / per$150.00 USDSale price $90.00 USDSale -

8.3" Chef Knife 440C Forged Steel

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $40.00 USDRegular priceUnit price / per$77.85 USDSale price $40.00 USDSale -

8.3" Chef Knife German 1.4116 Steel

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $32.47 USDRegular priceUnit price / per$42.58 USDSale price $32.47 USDSale -

8" Chef knife German 1.4116 Steel

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $28.00 USDRegular priceUnit price / per$35.89 USDSale price $28.00 USDSale -

7.5" BOONLION Nakiri Knife "BRH-N695"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

7.5" BOONLION Nakiri Knife "JRH-SKD11"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

7.6" BOONLION Chef Knife "BRH-N695"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

7.6" BOONLION Chef Knife "JRH-SKD11"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

8.7" Eagle Beef & Pork Bones Osteotomy Cleaver

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $75.59 USDRegular priceUnit price / per$120.25 USDSale price $75.59 USDSold out -

8.9" Butcher Slaughter Cleaver

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $55.00 USDRegular priceUnit price / per$82.00 USDSale price $55.00 USDSale -

7" Hand-Forged Serbian Cleaver

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $40.00 USDRegular priceUnit price / per$65.00 USDSale price $40.00 USDSale -

7.9" Rectangle Bone Cleaver for Beef & Pork

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $50.00 USDRegular priceUnit price / per$74.99 USDSale price $50.00 USDSold out -

Sold out

Sold out7.9" Beef & Pork Bone Cleaver

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $45.39 USDRegular priceUnit price / per$55.59 USDSale price $45.39 USDSold out -

8.3" Curved Blade Cleaver

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $45.00 USDRegular priceUnit price / per$55.00 USDSale price $45.00 USDSale -

7.4" Japanese Hitachi SLD Steel (JIS SKD11) Cleaver Knives with G10 Black glass fiber handle.

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $90.00 USDRegular priceUnit price / per$120.00 USDSale price $90.00 USDSale

BOONLION Tactical Edge (EDC)

The BOONLION Tactical Edge (EDC) is the ultimate companion for outdoor enthusiasts and adventurers, designed for a wide range of tactical uses such as camping, fishing, and traveling. Whether you're setting up camp, prepping food, cutting through tough materials, or handling emergency situations, this versatile knife excels in performance and reliability. Crafted by a skilled company with over 35 years of experience, the BOONLION Tactical Edge is forged from high-carbon 7Cr17MoV, 420J2, 5Cr15MoV, Japanese DC53, D2, and Bohler M390 steels, ensuring exceptional durability, corrosion resistance, and a razor-sharp edge that lasts.

This tactical knife is engineered for ease of carry and quick access, making it an essential tool for everyday carry (EDC) enthusiasts. The premium materials used ensure the knife holds up under various conditions, whether you're outdoors, on the go, or in need of a reliable tool for daily tasks. From the precision of the Japanese DC53 steel to the toughness of D2 and Bohler M390, each blade is crafted for optimal performance, making it a must-have for those who rely on their gear in challenging environments. Whether you're an avid camper, fisherman, or traveler, the BOONLION Tactical Edge (EDC) is designed to meet all your tactical knife needs with strength, versatility, and craftsmanship.

-

7" Hmong Bowie Copper Laminated AU

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $450.00 USDRegular priceUnit price / per -

7" BOONLION Mini Cutting Knife "BRM-N965"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $400.00 USDRegular priceUnit price / per -

8.7" BOONLION Black Bowie Knife "BRB-N695"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $450.00 USDRegular priceUnit price / per -

Sold out

Sold out8.7" BOONLION Bowie Knife "BRB-N695"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $450.00 USDRegular priceUnit price / per -

6.7" BOONLION Tactical Camp Knife "BRH-N965"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

6.7" BOONLION Tactical Camp Knife "JRH-SKD11"

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $250.00 USDRegular priceUnit price / per -

Sale

Sale7" Mini-Rambo Knife

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $135.23 USDRegular priceUnit price / per$222.75 USDSale price $135.23 USDSale

BOONLION Kitchen Shears

Experience unmatched cutting power with BOONLION Kitchen Shears, available in two premium stainless steel options—420J2 and 5Cr18. Both are engineered for sharpness, rust resistance, and durability, giving you professional-grade performance whether you're slicing through chicken bones, fish, herbs, or tough packaging. Choose 420J2 for everyday kitchen tasks with a balance of strength and affordability, or upgrade to 5Cr18 for even greater hardness and edge retention—perfect for heavy-duty or outdoor use. No matter your choice, you'll enjoy the same ergonomic, non-slip grip and ambidextrous comfort that makes BOONLION Shears a trusted companion in the kitchen, at the BBQ, or on your next fishing trip.

-

Sold out

Sold outBOONLION 420J2 Scissors C4

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $17.99 USDRegular priceUnit price / per$22.99 USDSale price $17.99 USDSold out -

BOONLION Premium Multi-Purpose Scissors C1

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $43.99 USDRegular priceUnit price / per$55.79 USDSale price $43.99 USDSale -

BOONLION 420J2 Stainless Steel Scissors C3

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $15.99 USDRegular priceUnit price / per$19.52 USDSale price $15.99 USDSale -

BOONLION Premium Multi-Purpose Scissors C2

Vendor:BOONLION WHOLESALE & RETAIL LLCRegular price $40.00 USDRegular priceUnit price / per$52.19 USDSale price $40.00 USDSale

Video

BOONLION KNIVES

Custom Kydex Sheath Service

At Boonlion Knives, we specialize in crafting high-quality custom Kydex sheaths tailored to fit your knife perfectly. Our sheaths provide superior protection, durability, and convenience for carrying your blade securely.

Boonlion Knives

Professional Knife Sharpening Service:

Professional Knife Sharpening Service

Keep your blades performing at their best with our precision sharpening services. Whether your knife is dull, chipped, or simply needs a touch-up, we use expert sharpening techniques to restore its razor-sharp edge.

Vacuum Heat Treatment with Deep Cryogenic Hardening and Tempering

Deep-Cooled Performance Steel

Vacuum deep-cooling heat treatment—also known as vacuum sub-zero or cryogenic treatment—is a high-precision thermal process that dramatically enhances the performance of high-carbon and tool steels, especially in knife making. The process begins with vacuum heat treatment, where the steel is heated in a vacuum furnace at temperatures around 1000–1100°C (1800–2000°F), eliminating oxygen to prevent oxidation and ensure a clean, controlled hardening environment. This improves the blade’s hardness, strength, and purity. Next, the blade undergoes quenching, rapidly cooling in oil or inert gas to lock in its hardened structure. It is then subjected to deep cryogenic cooling, where temperatures drop to as low as -196°C (-320°F) using liquid nitrogen. This phase transforms retained austenite into martensite, the hardest steel phase, significantly boosting wear resistance, edge retention, dimensional stability, and long-term toughness. Finally, the blade is tempered—gently reheated to 150–200°C (300–400°F)—to reduce brittleness while preserving its improved hardness. The result is a blade with exceptional cutting performance, superior structural stability, and lasting durability.

Oil Heat Treatment

Forged & Oil-Hardened

Oil heat treatment is a widely used method for hardening steel blades. The process begins by heating the steel to a high temperature—typically between 800°C and 1100°C (1470°F to 2010°F)—to transform its internal structure into austenite. Once heated, the blade is rapidly cooled by immersing it in oil, which provides a faster quench than air while being gentler than water, helping to prevent cracking or warping. This cooling phase transforms the austenite into martensite, a strong, hard crystal structure that greatly enhances the blade’s edge retention and durability. After quenching, the blade is often tempered at a lower temperature to relieve brittleness and improve toughness. Knife makers prefer oil heat treatment because it offers efficient hardening, superior edge performance, and a reduced risk of structural damage during the quenching process.

Collections

-

BOONLION HMONG CLASSIC & MODERN KNIVES

At BOONLION, we carefully select only high-performance steels to forge our Hmong...

-

BOONLION Professional Chef Knife

At BOONLION, we carefully select premium steels known for their razor-sharp edges,...

-

BOONLION Tactical Edge (EDC)

The BOONLION Tactical Edge (EDC) is the ultimate companion for outdoor enthusiasts...

-

BOONLION Kitchen Knife Set

The BOONLION Kitchen Knife Set offers a range of high-quality knives designed...